-

+86-13404286222

-

hmjxboss@gmail.com

INQUIRE NOW

+86-13404286222

hmjxboss@gmail.com

INQUIRE NOW

Introduction to Jiangyin Huanming Machinery Co., Ltd.

2024-03-01The role of mechanical processing in the field of nuclear energy?

2024-03-18Introduction to the Application of Mechanical Processing in the Marine Industry?

2024-03-19How can mechanical processing improve the performance and reliability of wind turbines?

2024-03-26What are the applications of machining in the field of wind power metallurgy?

2024-03-27Large compressors undoubtedly play a vital role in the efficient operation of modern industry. Among the core components of the compressor, the Large Compressor Shaft Rotor can be called the "heart" of the entire system, and its performance directly determines the stability, efficiency and life of the equipment.

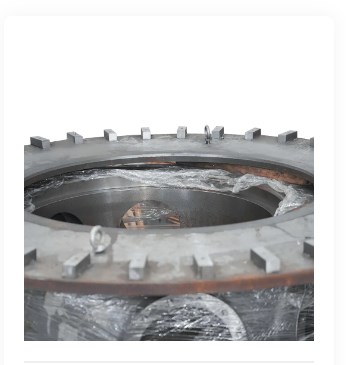

1. What is Large Compressor Shaft Rotor?

The shaft rotor is a key rotating component in the compressor that transmits mechanical energy to the working medium. It is usually composed of a main shaft (shaft) and multiple rotor impellers (rotors) installed on it. In heavy equipment such as large centrifugal compressors and axial flow compressors, the shaft rotor needs to withstand strong centrifugal force, thermal expansion and contraction, and fluid dynamic loads under high-speed rotation, so the structural design and material performance requirements are extremely high.

2. Analysis of the core structure: "precision mechanics" of the rotor

The typical structure of the shaft rotor of a large compressor includes:

Main shaft: usually a high-strength forging with excellent tensile and torsion resistance;

Impellers: a key energy conversion component installed on the main shaft, with a high-precision dynamic balance design;

Keyway or expansion sleeve connection: the connection method must ensure reliable stability under high-speed rotation;

End bearings and sealing systems: used to support the shaft rotor and prevent gas leakage.

Especially in multi-stage compression systems, the shaft rotor often reaches several meters in length, and must maintain extremely high coaxiality and moment of inertia control under dynamic conditions, making manufacturing and assembly extremely difficult.

3. Material selection is particular: high-performance alloys achieve stable operation

The performance of the shaft rotor of a large compressor depends largely on its material. Common materials include:

Nickel-based alloy steel (such as Inconel 718): high temperature and corrosion resistance, suitable for natural gas and petrochemical fields;

High-strength alloy steel (such as 40CrNiMoA, 17-4PH): good mechanical properties and processing performance;

Titanium alloy (some aviation or special environment applications): light and high strength, but high cost.

The selection of materials needs to comprehensively consider multiple factors such as temperature, pressure, medium corrosiveness and rotation speed. In addition, the material needs to have good machinability to meet the requirements of subsequent heat treatment and dynamic balancing processing.

4. The whole process of manufacturing process: precise interpretation from forging to dynamic balancing

Rough machining and forging: high-strength forgings are selected as blanks, and internal defects are eliminated through multiple forgings;

Precision machining: dimension machining and contour forming are completed through CNC turning and milling equipment;

Heat treatment process: such as tempering, quenching, aging treatment, etc., to improve strength and toughness;

Dynamic balancing adjustment: high-speed shaft rotors need to be strictly tested on the dynamic balancing test bench to control the unbalanced quality;

Non-destructive testing: ultrasonic, magnetic powder, X-ray and other methods are used to detect internal defects to ensure safety;

Surface treatment and corrosion protection: nickel plating, phosphating and other methods are often used to extend the service life.

The shaft rotor also needs to be finely aligned as a whole and cold + hot deformation compensation design during the assembly stage, which places extremely high demands on the technical capabilities of the manufacturer.

5. Wide application areas: key power components from energy to aviation

Large compressor shaft rotors are widely used in the following fields:

Petrochemical industry: natural gas booster stations, catalytic cracking units, etc.;

Metallurgy and fertilizer industry: ammonia compression, synthesis gas transportation;

Energy industry: thermal power plant gas turbine system, CCUS device;

Aerospace: turbo compressor rotor as its core power unit;

Liquefied gas and refrigeration industry: large refrigeration compressors in low temperature environments.

Large Compressor Shaft Rotor is the "lifeline" component that supports the efficient operation of the modern industrial system. It integrates mechanics, materials science, processing technology and automated monitoring systems, and is an important manifestation of the level of high-end equipment manufacturing. In the future, with the localization of high-end equipment, the advancement of intelligent manufacturing and the development of the clean energy industry, shaft rotor technology will usher in a broader stage.

No. 16 Dayuanli Road, Yunting Street, Jiangyin City, Jiangsu Province, China

No. 16 Dayuanli Road, Yunting Street, Jiangyin City, Jiangsu Province, China

+86-13404286222 / +86-13404286222

+86-13404286222 / +86-13404286222

+86-510-86668678

+86-510-86668678

hmjxboss@gmail.com

hmjxboss@gmail.com

Copyright © Jiangyin Huanming Machinery Co., Ltd. All Rights Reserved.Custom Large Components Mechanical Processing Manufacturers