Coiler shaft accessories: the indispensable heart of the metallurgical production line, its importance should not be underestimated?

In the vast industrial landscape, the metallurgical industry stands at the top of the times with its unique charm. It is not only the cornerstone of modern civilization progress, but also an important manifestation of the country's economic strength and scientific and technological level. In this hot and vibrant field, the coiling shaft accessories, as the "heart" of the metallurgical production line, carry extraordinary missions and responsibilities, silently pushing the steel giant wheel forward.

Metallurgy, an ancient and ever-new industry, has been with human civilization since its birth. From the initial simple smelting to today's modern production line, metallurgical technology has been constantly innovating, providing a continuous source of power for the development of human society. In this magnificent metallurgical picture, the coiling shaft accessories, with their unique status and role, have become a bridge connecting raw materials and finished products, technology and the market.

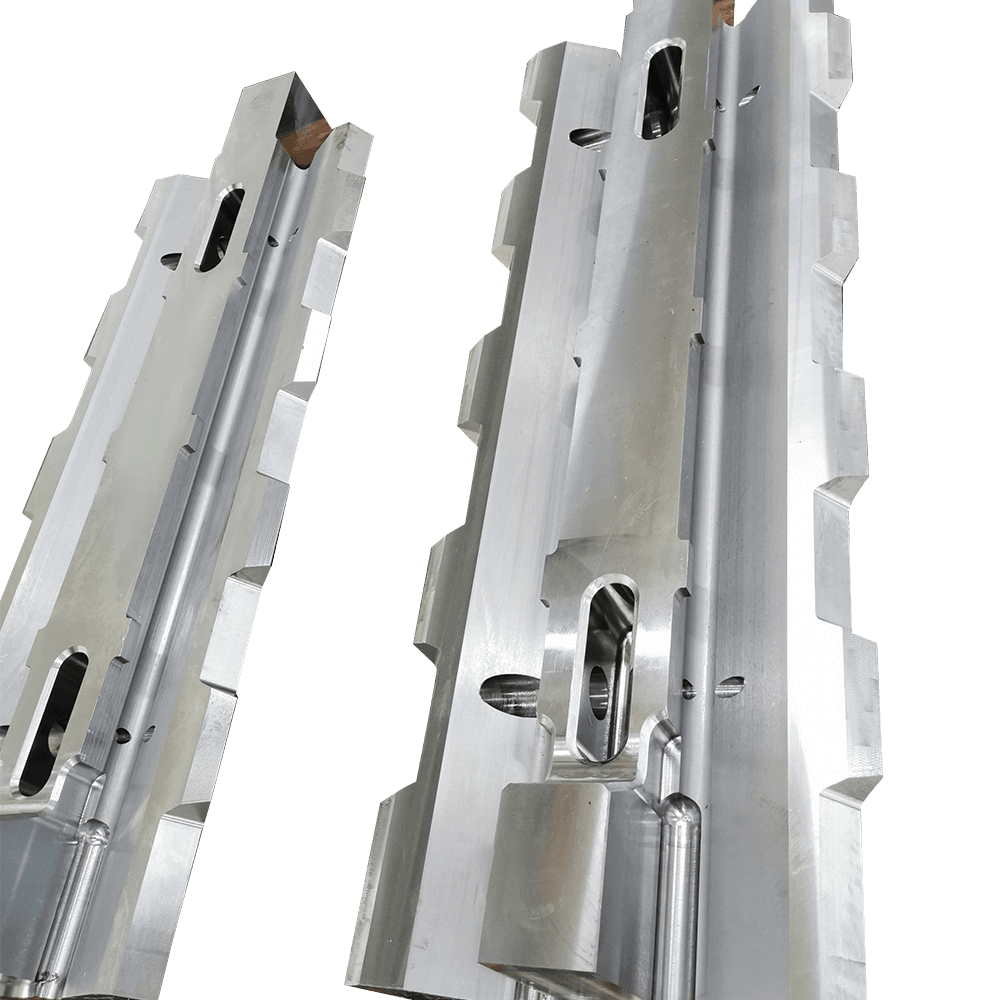

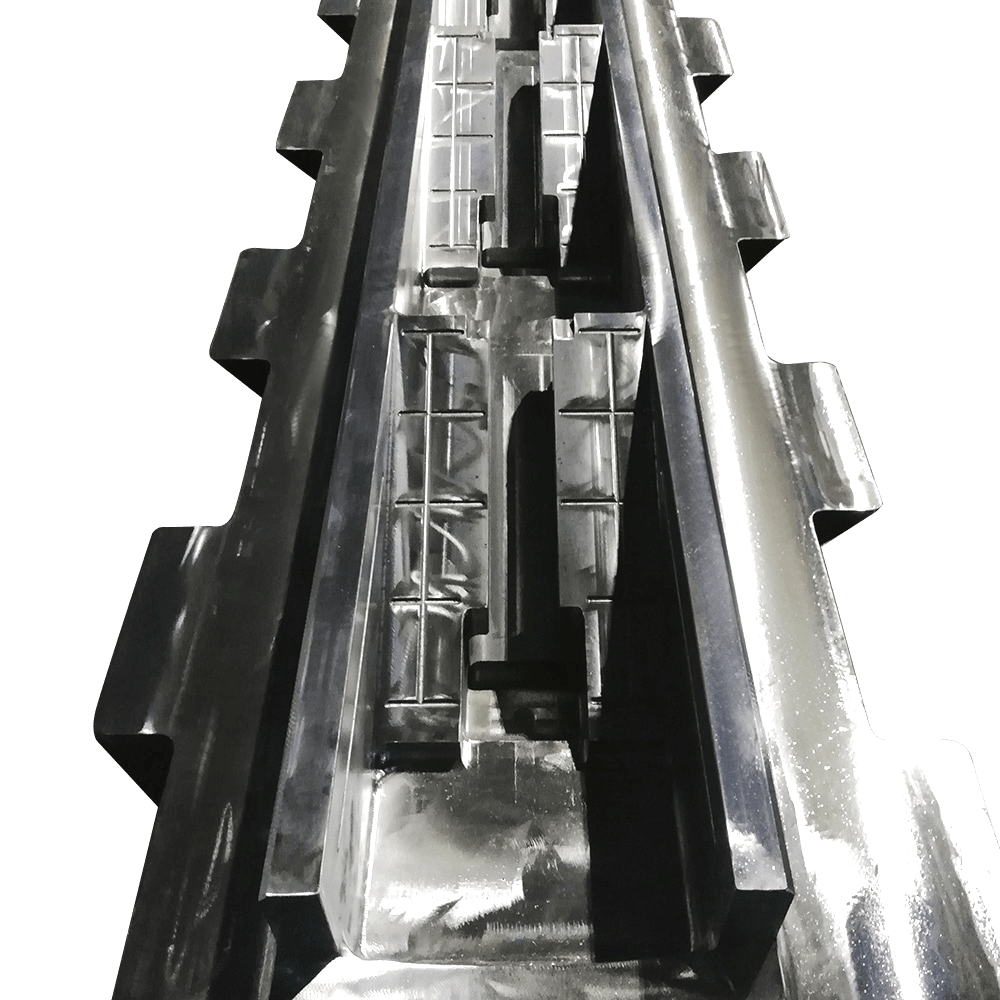

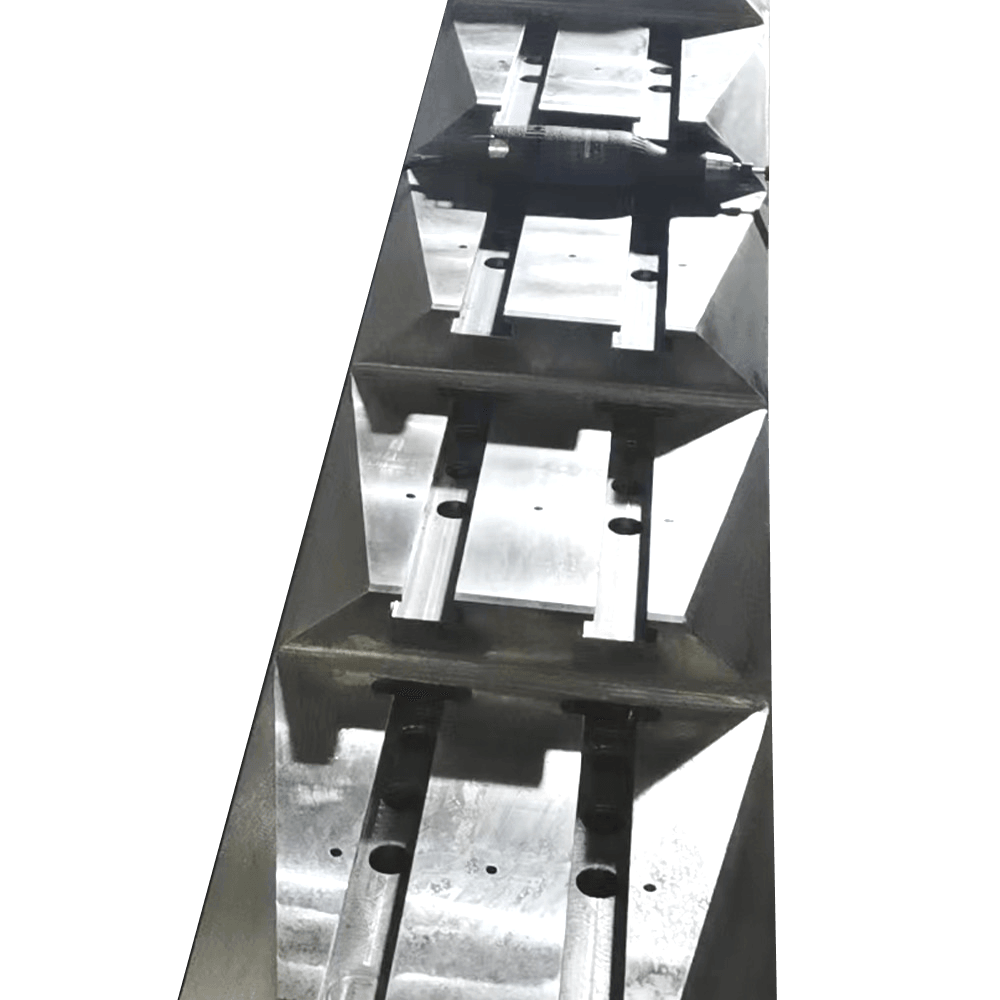

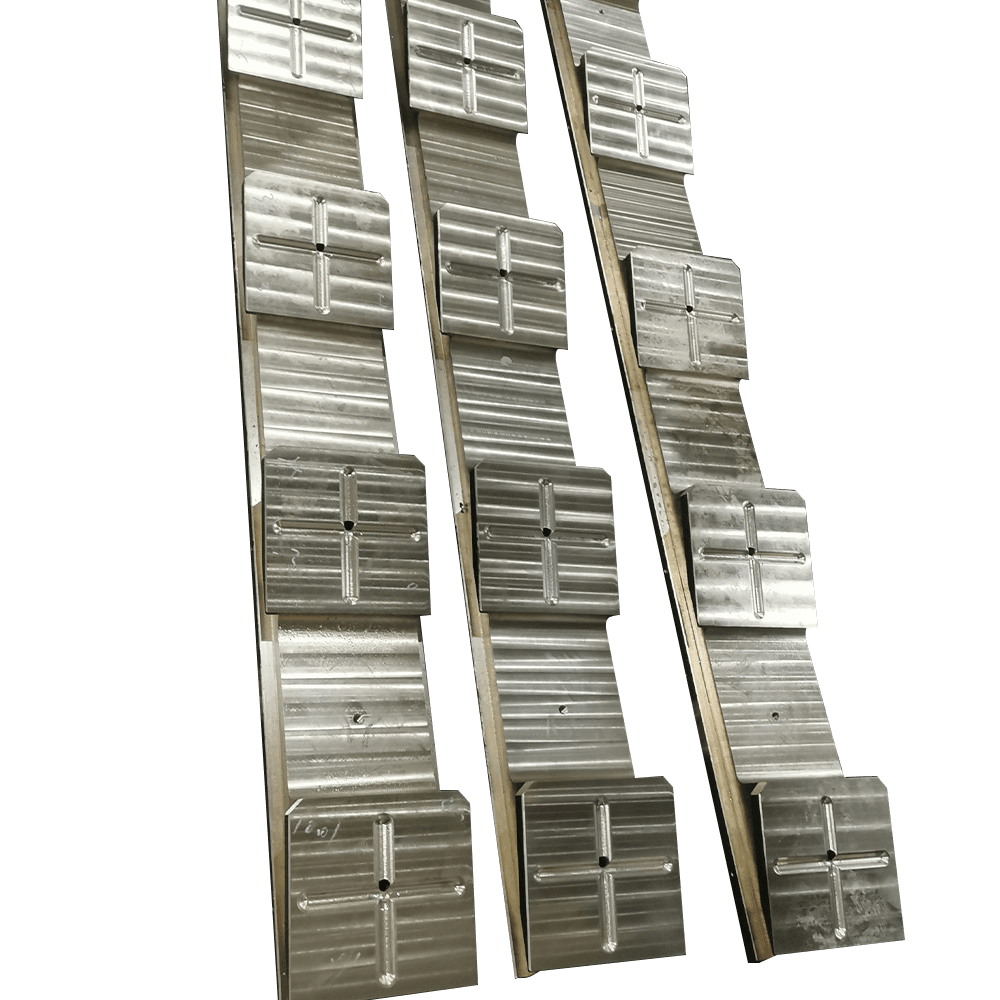

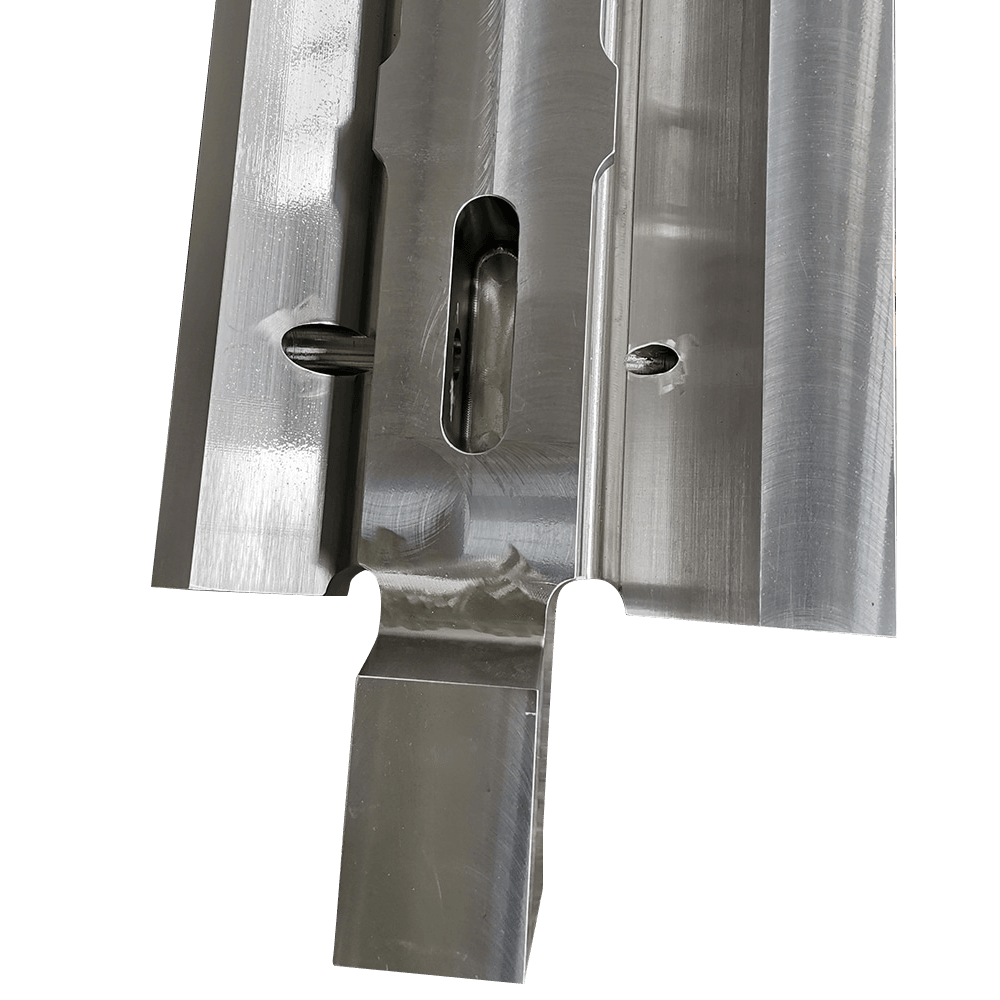

In the metallurgical production line, coiling shaft accessories play a vital role. Their main task is to smoothly and quickly coil the steel after hot rolling, cold rolling and other processes into coils for subsequent storage, transportation and processing. This seemingly simple action actually contains extremely high technical content and complexity.

Coil shaft accessories must be able to withstand extremely high temperatures and pressures. During metallurgical production, the temperature of steel is often as high as hundreds or even thousands of degrees Celsius, accompanied by huge mechanical stress. This requires that the coil shaft accessories must have excellent high temperature resistance, wear resistance and fatigue resistance to ensure stable operation under extreme working conditions.

The precision and stability of coil shaft accessories are crucial to product quality. The coiling quality of steel directly affects the appearance, size and performance of the finished product. Therefore, the design, manufacturing and installation of coil shaft accessories must meet extremely high precision standards to ensure that each roll of steel can meet the established quality requirements.

The intelligence and automation level of coil shaft accessories is also an important indicator of the degree of modernization of metallurgical production lines. With the continuous development of science and technology, more and more metallurgical enterprises have begun to introduce intelligent and automated coiling systems, which integrate advanced sensors, controllers and actuators to achieve precise control and real-time monitoring of the coiling process. This not only improves production efficiency and product quality, but also greatly reduces labor costs and labor intensity.

Faced with increasingly fierce market competition and ever-changing market demands, the metallurgical industry must continue to innovate, take science and technology as the guide, and promote industrial upgrading and transformation. In this process, as one of the core components of the metallurgical production line, the technological innovation and upgrading of the coiling shaft accessories are particularly important.

The extraordinary mission of the coiling shaft, the heart of metallurgy, is not only reflected in its direct impact on production efficiency and product quality, but also in its role in promoting the development of the entire metallurgical industry. In the future development, with the continuous advancement of science and technology and the deepening of innovation, the coiling shaft accessories will continue to contribute to the prosperity and development of the metallurgical industry with more outstanding performance and more intelligent performance.

English

English 中文简体

中文简体 русский

русский 日本語

日本語 Español

Español