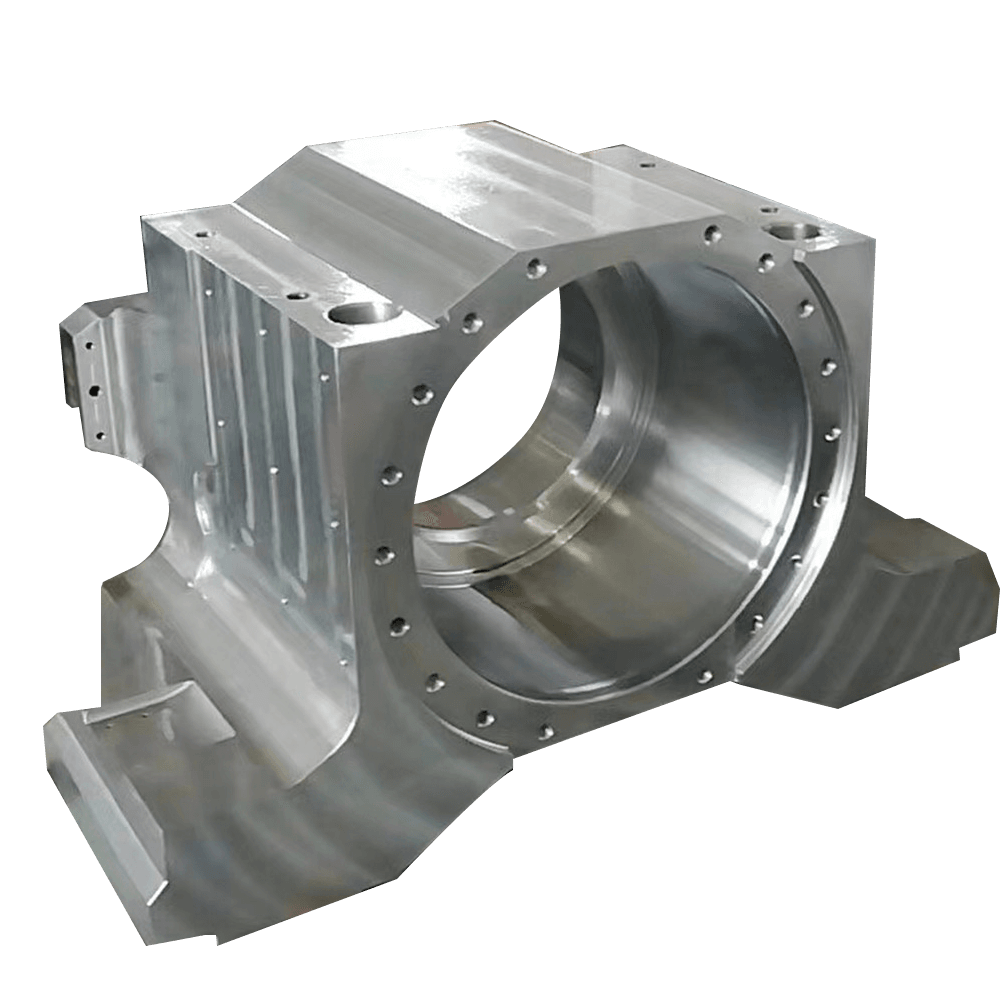

What are the key technical parameters in the design and manufacturing process of universal bearing seats?

In the design and manufacturing process of universal bearing seats, the key technical parameters include the following aspects:

Carrying capacity: Universal bearing seats need to be designed according to the load conditions in the use environment to ensure that they can withstand the corresponding axial and radial loads.

Bearing type and size: Select the appropriate bearing type (such as deep groove ball bearings, tapered roller bearings, etc.) and size to meet specific application requirements.

Material: The material selection of the bearing seat is very important. Commonly used materials include cast iron, steel, aluminum alloy, etc. The specific selection needs to consider factors such as strength, wear resistance and corrosion resistance in the use environment.

Lubrication system: Lubrication is the key to ensure the normal operation of the universal bearing seat. The design needs to consider the selection of lubricants, lubrication methods (such as oil bath lubrication, oil mist lubrication, etc.) and the layout of the lubrication system.

Sealing: In order to prevent external contaminants from entering the bearing, the type of sealing structure (such as labyrinth seals, contact seals, etc.) and the sealing effect need to be considered during design.

Installation method: The installation method of the bearing seat (such as flange installation, base installation, etc.) needs to be determined according to the actual application scenario to ensure its stability and reliability.

Centering performance: The universal bearing seat needs to have good centering performance to adapt to slight deviation and vibration of the shaft and reduce wear on the bearing and equipment.

Temperature range: The operating temperature range of the bearing seat needs to be considered during design to select appropriate materials and lubricants to ensure its reliability in high or low temperature environments.

Accuracy level: Select the appropriate accuracy level according to application requirements to meet the accuracy requirements of equipment operation.

Vibration and noise control: Vibration and noise control measures need to be considered during design to ensure smooth operation of the equipment and comfort of the operating environment.

What are the common materials for universal bearing seats, and how to choose the right material?

Common materials for universal bearing seats include:

Cast iron: Cast iron is one of the commonly used materials with good mechanical properties and cost-effectiveness, suitable for general industrial applications.

Steel: Especially high-strength steel, which can provide higher load-bearing capacity and wear resistance, suitable for high-load and high-speed applications.

Aluminum alloy: Aluminum alloy is lightweight, has good thermal conductivity and corrosion resistance, and is suitable for applications that require lightweight and corrosion resistance.

Stainless steel: In situations where corrosion resistance is required, choosing stainless steel materials can ensure long-term and stable use.

The following factors should be considered when choosing the right material:

Load and speed: Select materials according to the load size and speed in the actual application to ensure that the bearing seat can withstand the corresponding force and operating speed.

Environmental conditions: Consider factors such as temperature, humidity, and chemicals in the working environment, and choose materials that can withstand these conditions.

Cost and manufacturing process: Consider the cost and processing difficulty of the material, and choose to minimize the manufacturing cost while meeting the performance requirements.

Maintenance and durability: Choose materials with good wear resistance, fatigue resistance and easy maintenance to extend the service life of the bearing seat and reduce maintenance costs.

Weight and lightweight requirements: Some applications may have strict requirements on the weight of the bearing seat, and lightweight materials need to be selected to meet this requirement.

English

English 中文简体

中文简体 русский

русский 日本語

日本語 Español

Español