Jiangyin Huanming Machinery Co., Ltd.

Jiangyin Huanming Machinery Co., Ltd. is located in Jiangyin City, a beautiful and prosperous water town known for its outstanding location, fresh and elegant surroundings, and easy transportation.

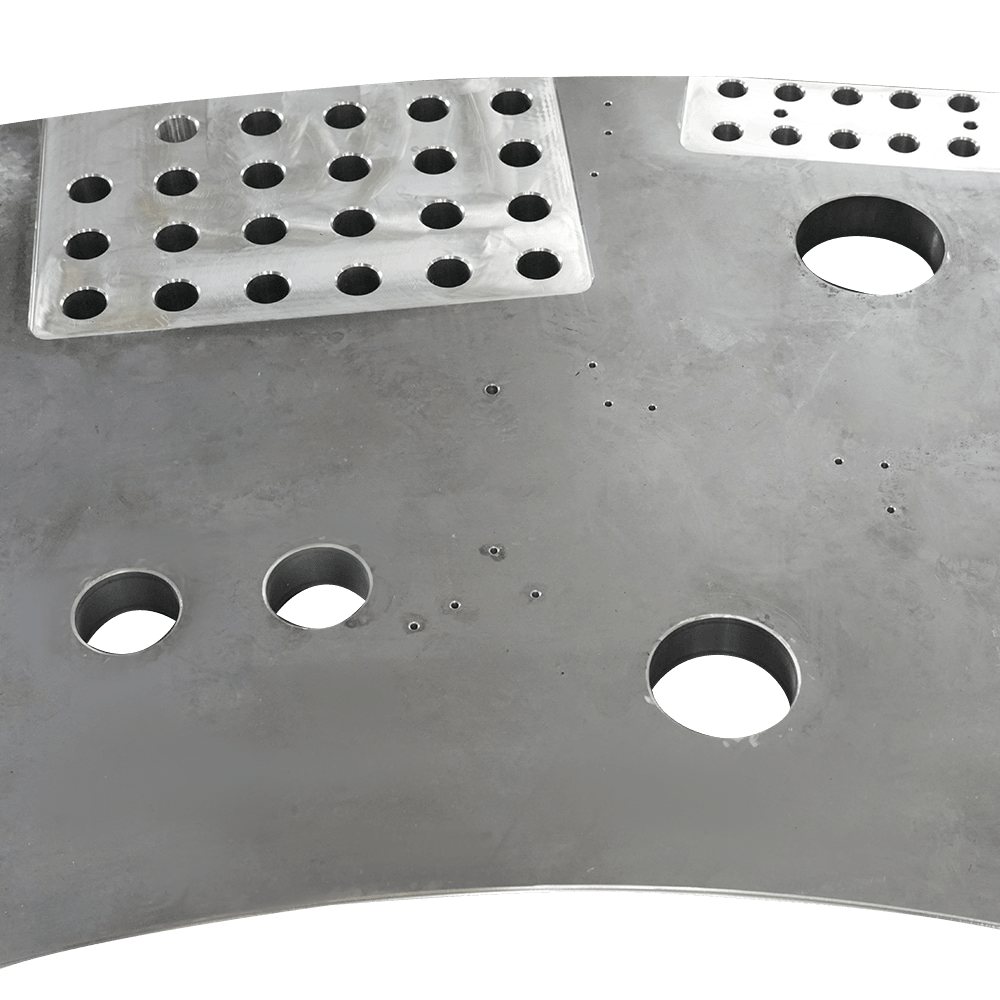

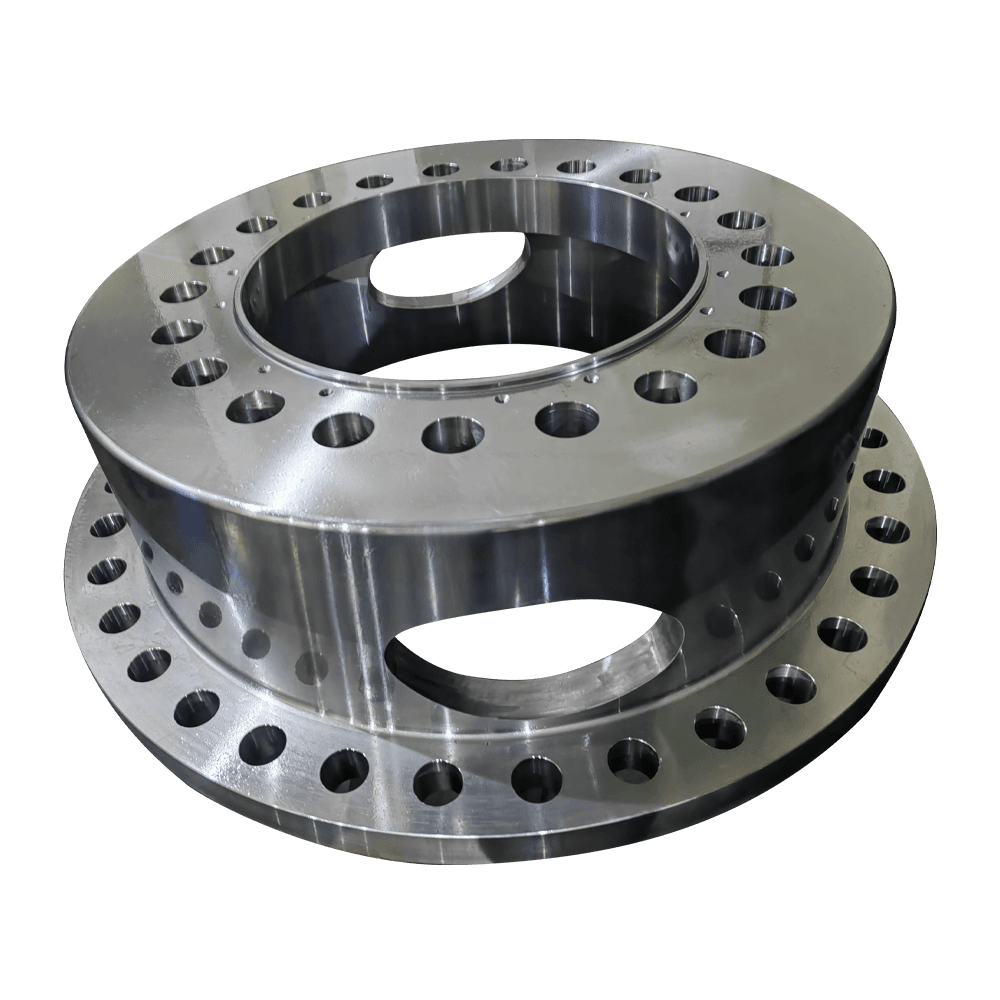

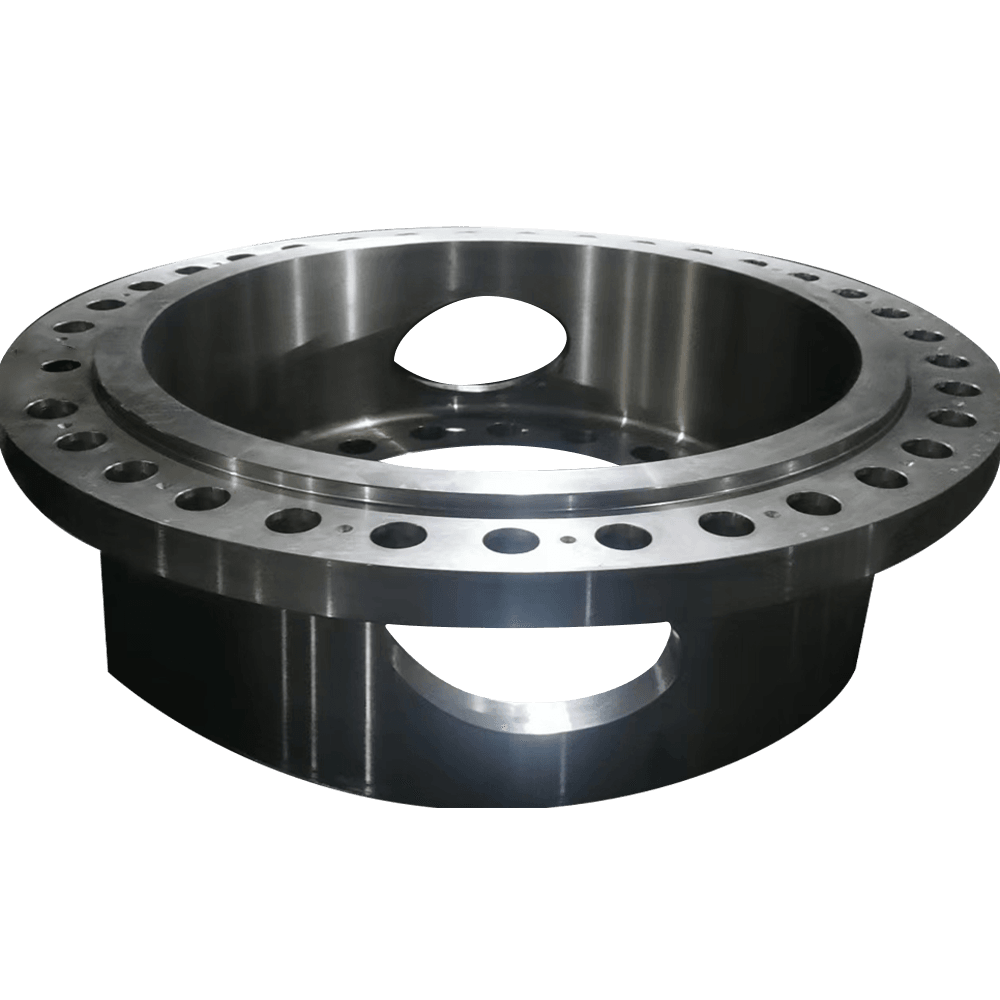

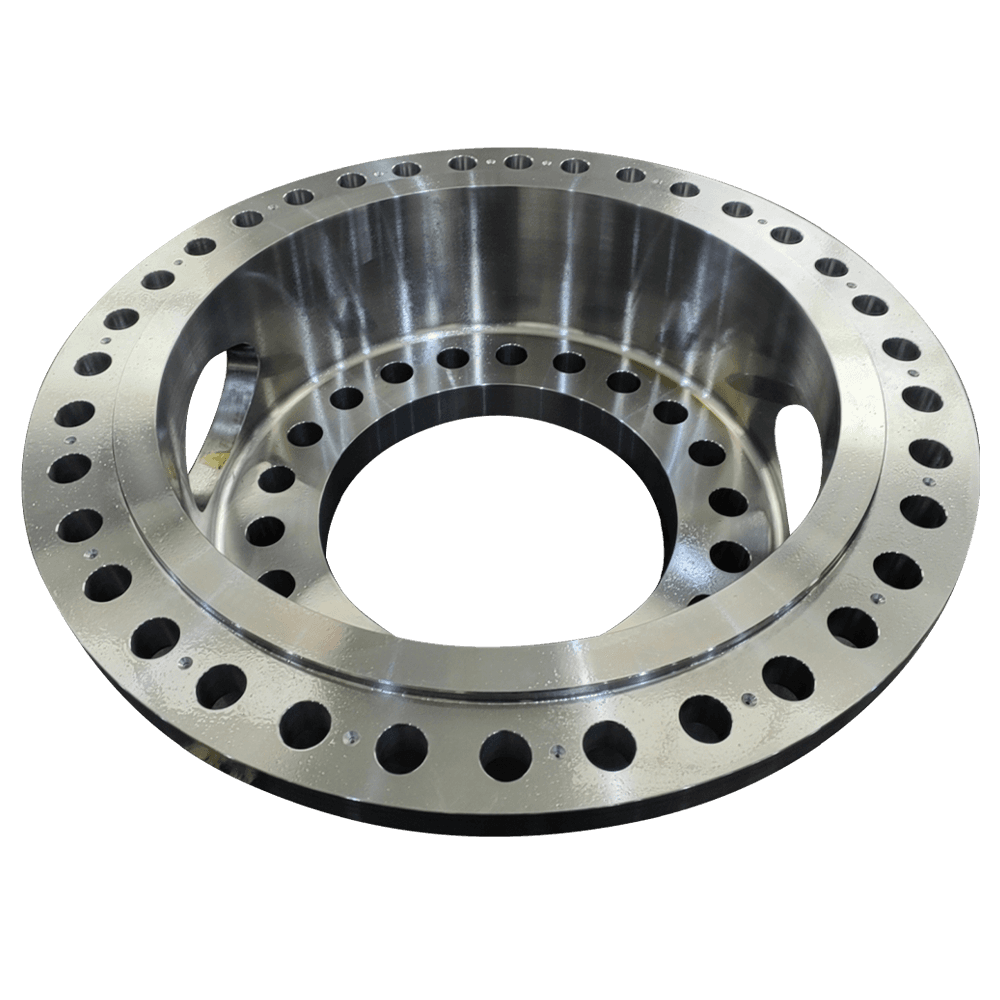

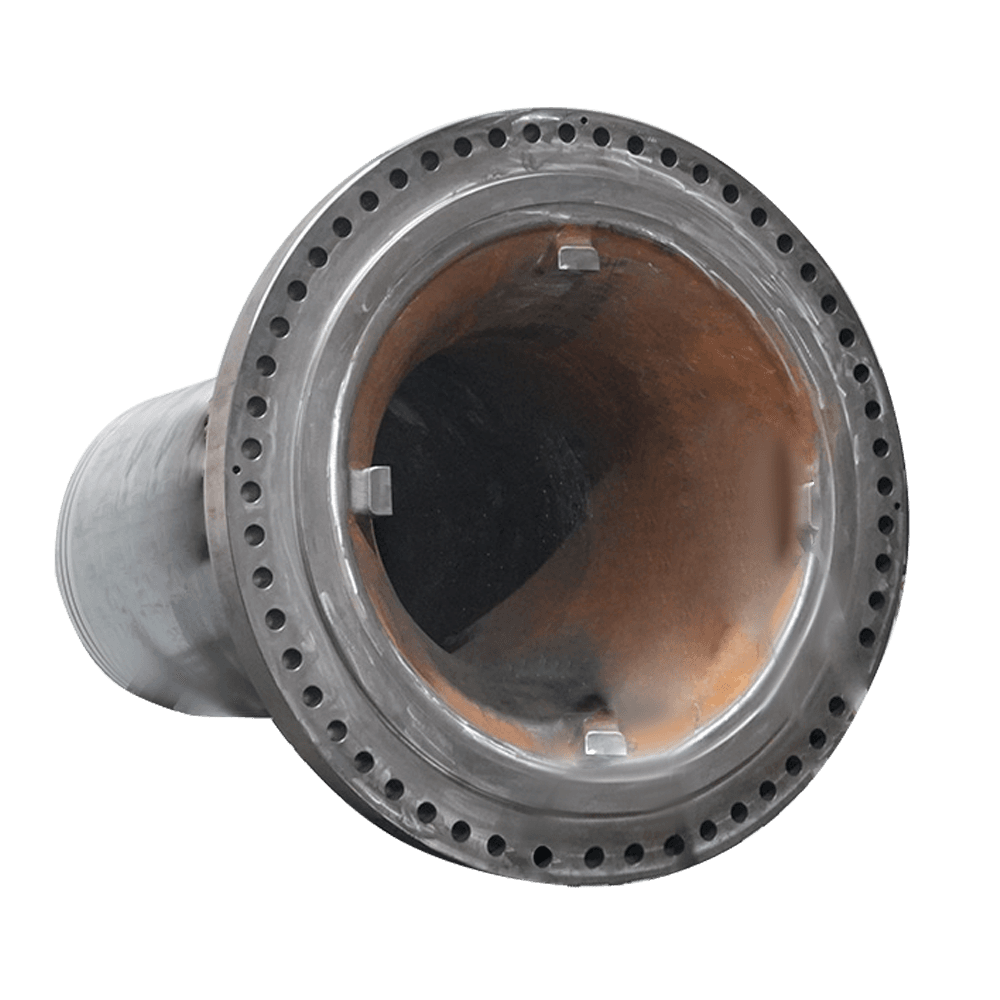

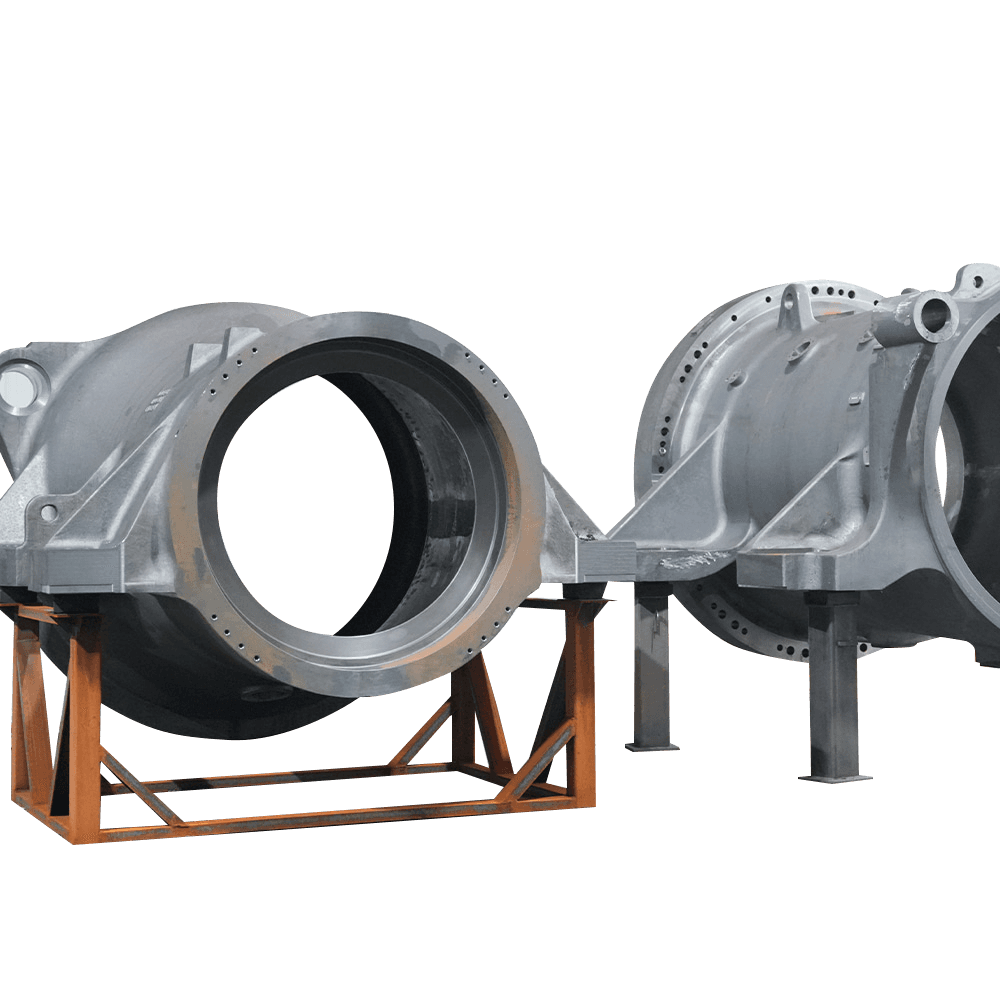

As a professional core supplier of large components, our products include oil well blowout preventers,

centrifuge drums, gearbox, large compressor cylinders, machine tool chucks, universal bearing

seats, racks, couplings, wind power gearboxes, planetary frames, etc. Our products are suitable

not only for metallurgical equipment, transmission equipment, new energy equipment, mining equipment,

machine tools, but also for the production and manufacturing of high-precision products such

as forgings, castings, and welded parts.

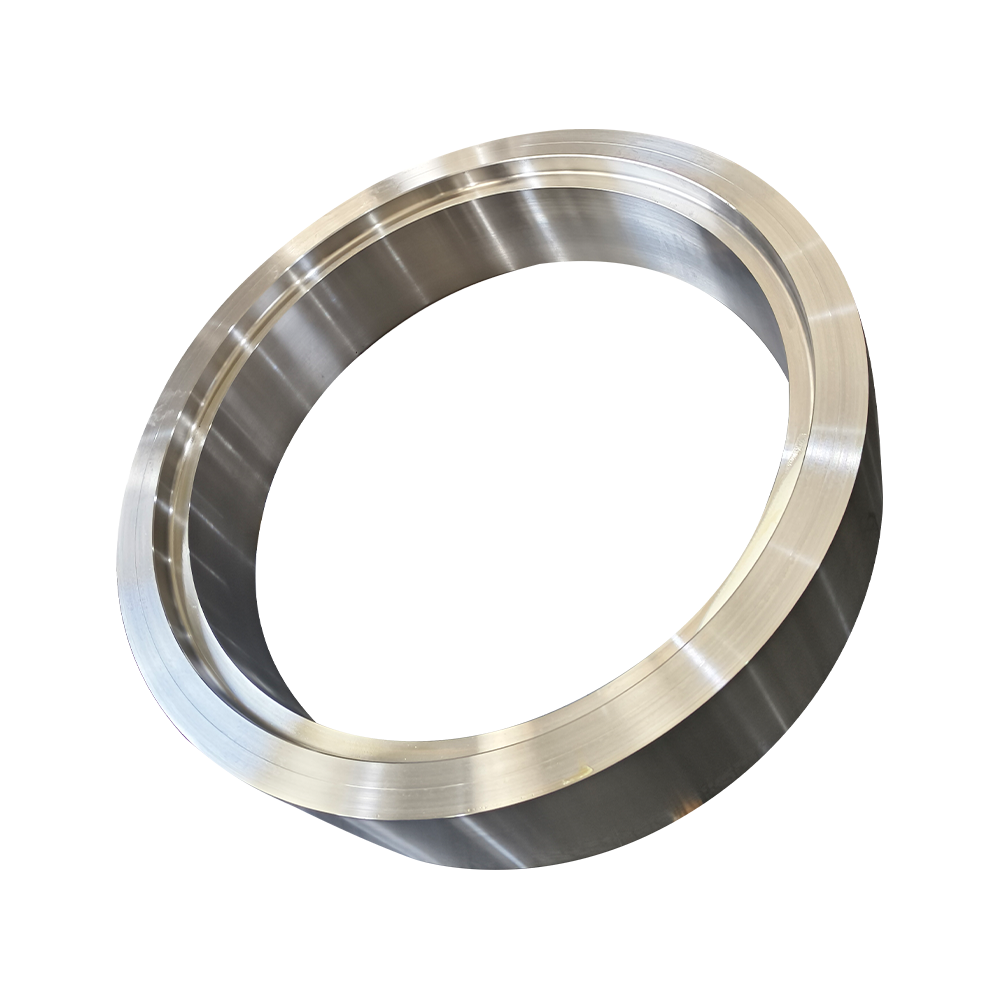

Our company's equipment includes horizontal machining centers, gantry machining centers, CNC boring

machines, high-speed CNC vertical lathes, vertical turning and milling composite equipment, etc.

The accuracy of the machine tools reaches 8 μm, and the precision requirements of the product

can be fully guaranteed, including machining, boring and milling, drilling, and simple assembly

work. We are China customWind power components Suppliers and OEM Wind power components Manufacturers, At the same time, our factory also has trained full-time inspectors who regularly calibrate

measuring instruments, including magnetic detector and Ultrasonic detectors, hardness testing

machine, Surface Roughmeter, and a set of Japanese Sanfeng micrometers, vernier calipers, and

other measuring tools.

The company has established good relationships with DANIELI, KOBELCO, ANDRITZ, and ROSS. Through

cooperation with numerous well-known enterprises, we have gained experience and progress, and

acquired experienced professional management and technical personnel. Over the years, precision-processed

products and normal delivery have enabled our business to operate well and enjoy a high reputation

among users. At the same time, we have attracted more customers and knowledgeable people to work

with us.

In the future, we will adhere to market-oriented development and quality-oriented development, continuously

improve our corporate philosophy, and commit to the concept of mutual benefit and win-win situation.

English

English 中文简体

中文简体 русский

русский 日本語

日本語 Español

Español