What are the key parameters and specifications to consider when choosing a chain winch?

The following key parameters and specifications need to be considered when choosing a chain winch:

Line Pull: The maximum pulling force of the chain winch is the key parameter that determines whether it can perform the expected work. The appropriate pulling force needs to be selected according to the size of the vessel and the weight of the anchor chain.

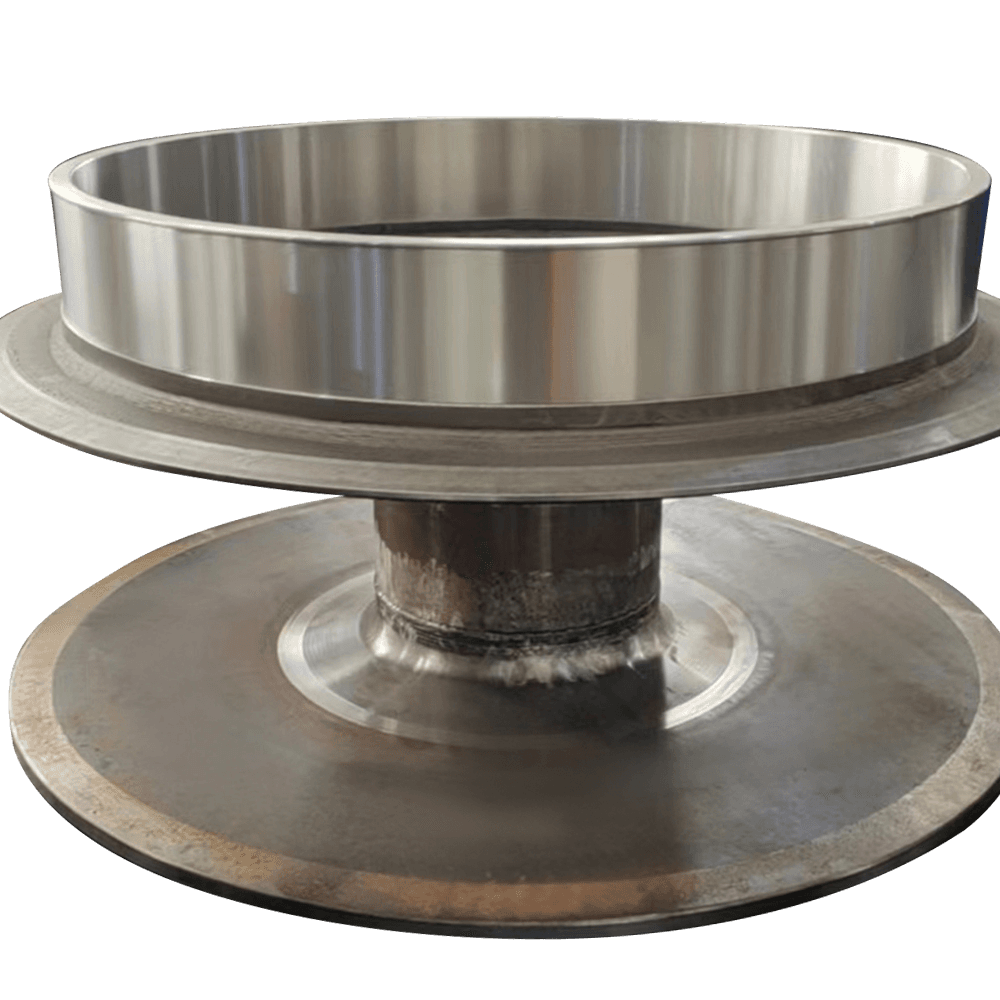

Chain Size: The chain winch must match the size of the anchor chain used. Chains of different diameters require corresponding specifications of winches.

Power Source: The chain winch can be electric or hydraulically driven. The appropriate drive method needs to be selected according to the power system on board.

Voltage and Power Rating: If an electric winch is selected, make sure its voltage and power match the power system on board.

Hauling Speed: The speed of the winch affects the efficiency of the anchor chain, usually expressed in meters per minute (m/min). The appropriate speed needs to be selected according to the operational requirements.

Brake System: A high-quality brake system can ensure safety and reliability during the operation of the chain winch. You need to understand the brake type and braking force of the winch.

Control System: The operation control system of the winch, including remote control, manual controller or automatic control system, needs to consider its ease of operation and safety.

Material of Construction: The material of the winch should be corrosion-resistant, especially when used in a marine environment. Common materials include stainless steel and galvanized steel.

Mounting Method: You need to consider whether the installation method of the winch is suitable for the structural layout of the ship to ensure stable installation and convenient operation.

Certifications and Standards: Choose a winch that is certified in accordance with relevant international and domestic standards (such as ISO, ABS, DNV, etc.) to ensure its quality and reliable performance.

What are the key points of maintenance of marine anchor chain winches, and how to extend their service life?

Maintenance of marine anchor chain winches is the key to ensure their normal operation and extend their service life. Here are some important maintenance points:

Maintenance points

Regular inspection

Appearance inspection: Regularly check the outside of the winch for corrosion, damage or loose parts.

Internal inspection: Check the wear of the mechanical parts inside the winch, including gears, bearings and seals.

Lubrication

Lubricate gears and bearings: Regularly add lubricating oil to gears and bearings to reduce friction and wear.

Check the amount of lubricating oil: Make sure there is enough lubricating oil and replace it as needed.

Cleaning

Cleaning the surface of the winch: Regularly remove salt stains, dirt and debris from the surface of the winch, especially in the marine environment, where salt will accelerate metal corrosion.

Internal cleaning: Disassemble the winch for internal cleaning as needed to remove accumulated impurities and sediments.

Fastener inspection

Check bolts and nuts: Make sure all bolts and nuts are tightened to avoid loosening during operation.

Check welding points: Check welding points for cracks or damage, and repair them in time.

Electrical system maintenance

Check electrical connections: Make sure electrical connections are tight and free of corrosion.

Check motors: Test the motor's operating status regularly to ensure it is working properly.

Braking system inspection

Check brakes: Make sure brakes are working properly and adjust or replace them if necessary.

Test braking force: Test braking force regularly to ensure it can effectively brake in an emergency.

Cable and remote control maintenance

Check cables: Make sure cables are not worn, broken or aged.

Test remote controls: Make sure the remote controls function properly and the buttons are sensitive.

Anti-corrosion treatment

Coating protection: Check and repair the anti-corrosion coating regularly to ensure it is intact.

Use rust inhibitors: Use rust inhibitors on key parts for protection.

Measures to extend service life

Correct use

Use in accordance with the operating manual: Use the winch strictly in accordance with the operating manual provided by the manufacturer to avoid overloading and misoperation.

Avoid excessive use: Avoid continuous use of the winch for a long time and give the mechanical parts proper rest time.

Environmental protection

Avoid harsh environments: Try to avoid using the winch in extremely harsh weather conditions to reduce the impact of the environment on it.

Protective measures: When not in use, take protective measures, such as covering the protective cover to prevent rain and salt spray erosion.

Timely repair

Fault handling: Handle any faults found in a timely manner to avoid small problems from developing into major faults.

Regular maintenance: Develop and implement a regular maintenance plan to ensure that the winch is in optimal working condition.

English

English 中文简体

中文简体 русский

русский 日本語

日本語 Español

Español