Why Are Large Compressor Shaft Rotors Crucial to Industrial Processes?

Large compressor shaft rotors are pivotal components in many industrial applications, playing a critical role in the efficient and reliable compression of gases. These sophisticated devices are integral to various sectors, from petrochemical plants and refrigeration systems to the production of liquefied natural gas (LNG) and chemical synthesis. Their design, materials, and operational precision significantly influence the overall performance and energy efficiency of the systems they serve.

Applications in Industry

Petrochemical Plants: In petrochemical plants, large compressor shaft rotors are essential for processes such as cracking, reforming, and the synthesis of various chemicals. They compress hydrocarbon gases to the required pressures for chemical reactions, facilitating the production of polymers, fertilizers, and fuels. The reliability and efficiency of these compressors directly impact plant productivity and operational costs.

Refrigeration Systems: Large-scale refrigeration systems, such as those used in industrial cooling and air conditioning, rely on compressor shaft rotors to compress refrigerants. This compression cycle is vital for the heat exchange process, enabling the cooling of spaces and materials. High-performance rotors ensure consistent temperature control, energy efficiency, and reduced operational wear and tear.

Liquefied Natural Gas (LNG) Production: In the LNG industry, natural gas must be compressed and cooled to extremely low temperatures to convert it into liquid form for storage and transportation. Compressor shaft rotors are crucial in this liquefaction process, handling the high pressures and volumes of gas. Their robust construction and precise engineering ensure the safety and efficiency of LNG plants, where any failure could result in significant safety hazards and financial losses.

Chemical Synthesis: Chemical synthesis processes often require the compression of gases to facilitate reactions under specific conditions of temperature and pressure. Large compressor shaft rotors are used in the synthesis of ammonia, methanol, and other chemicals. Their ability to maintain stable and high-pressure environments is essential for achieving desired chemical yields and maintaining process safety.

Design and Material Considerations

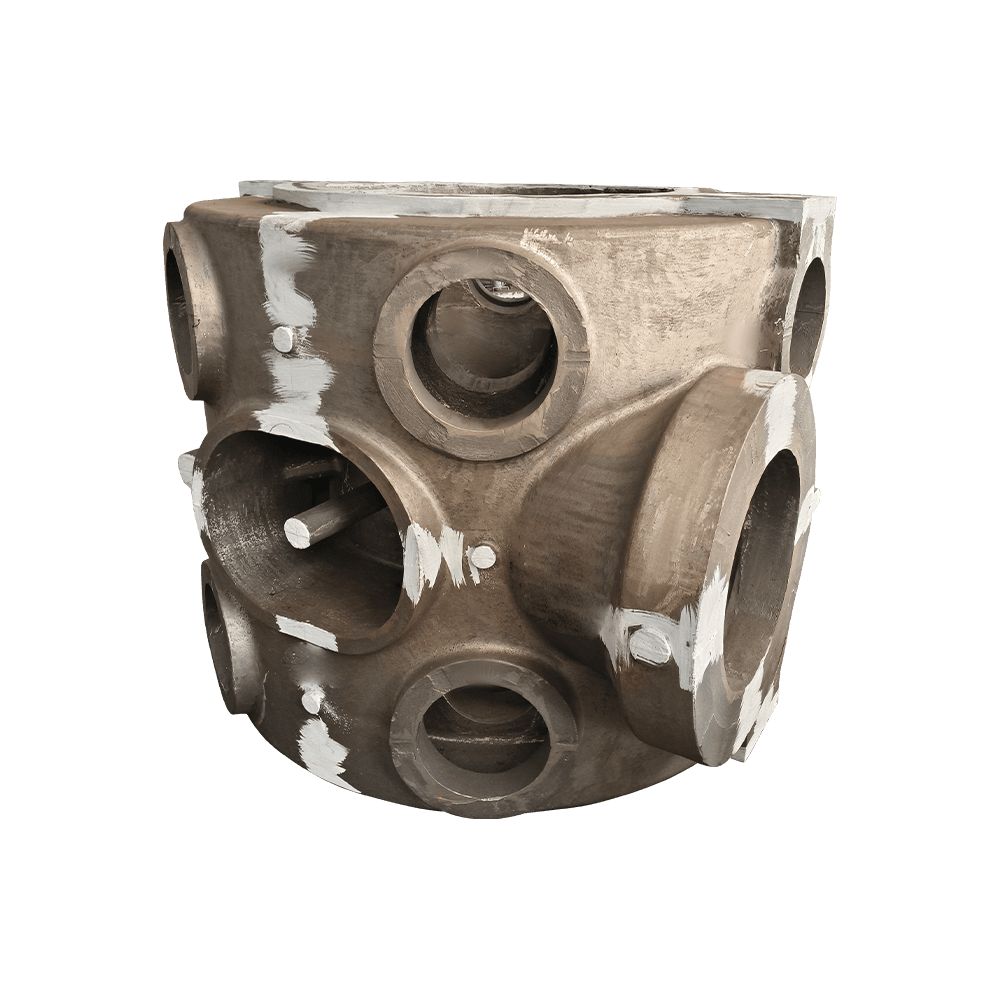

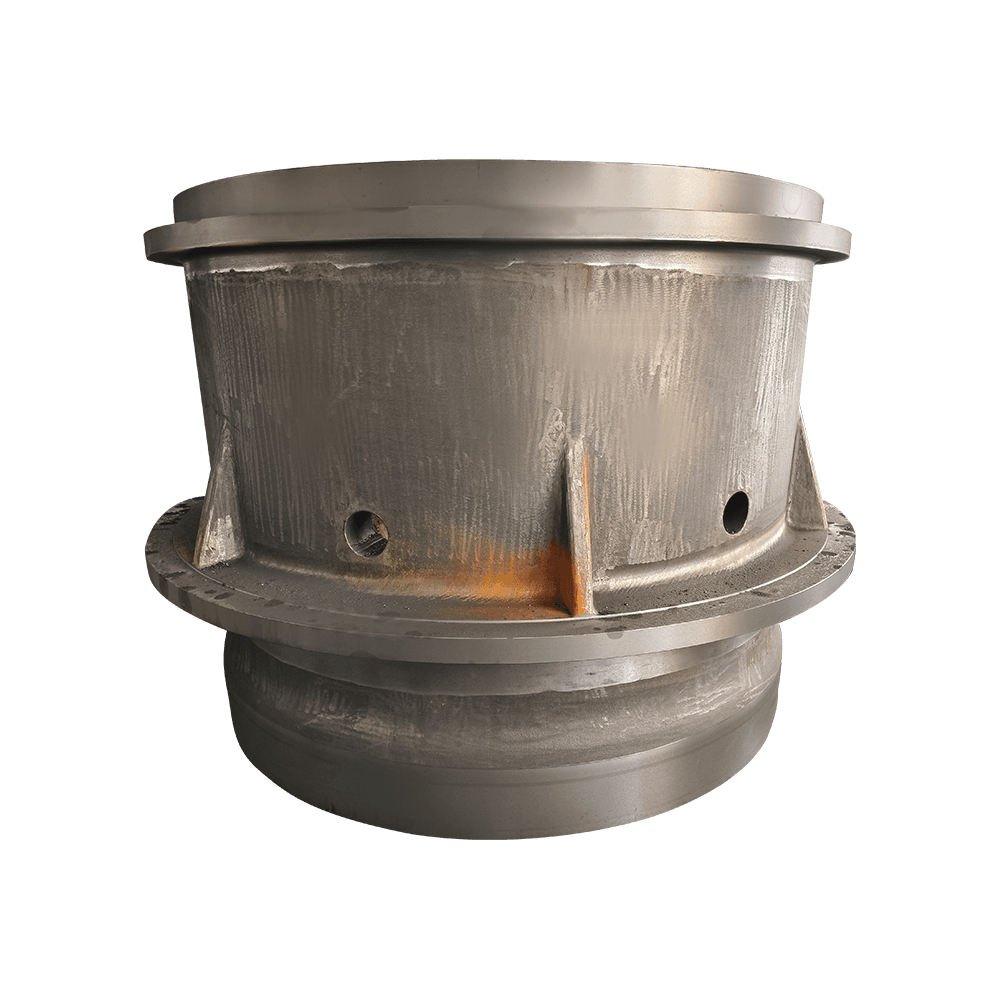

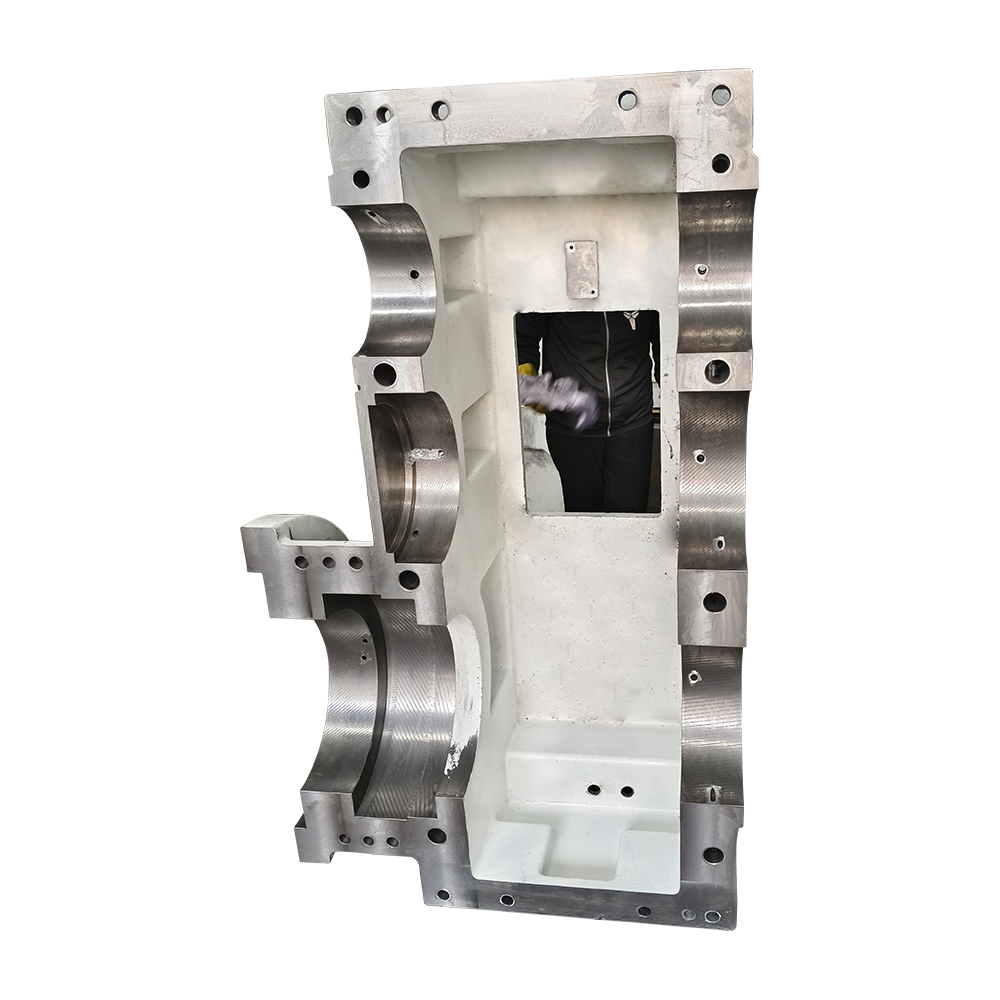

The design of large compressor shaft rotors involves meticulous engineering to balance durability, efficiency, and performance. Key considerations include:

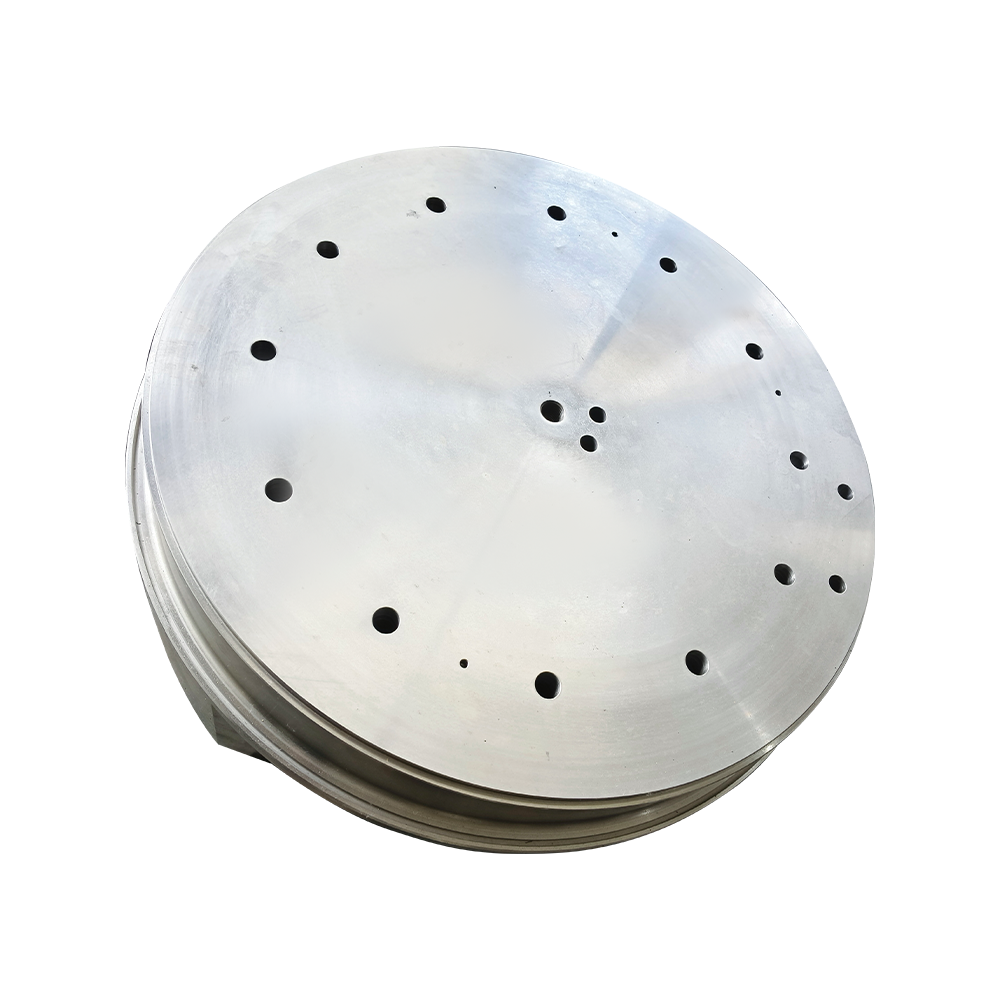

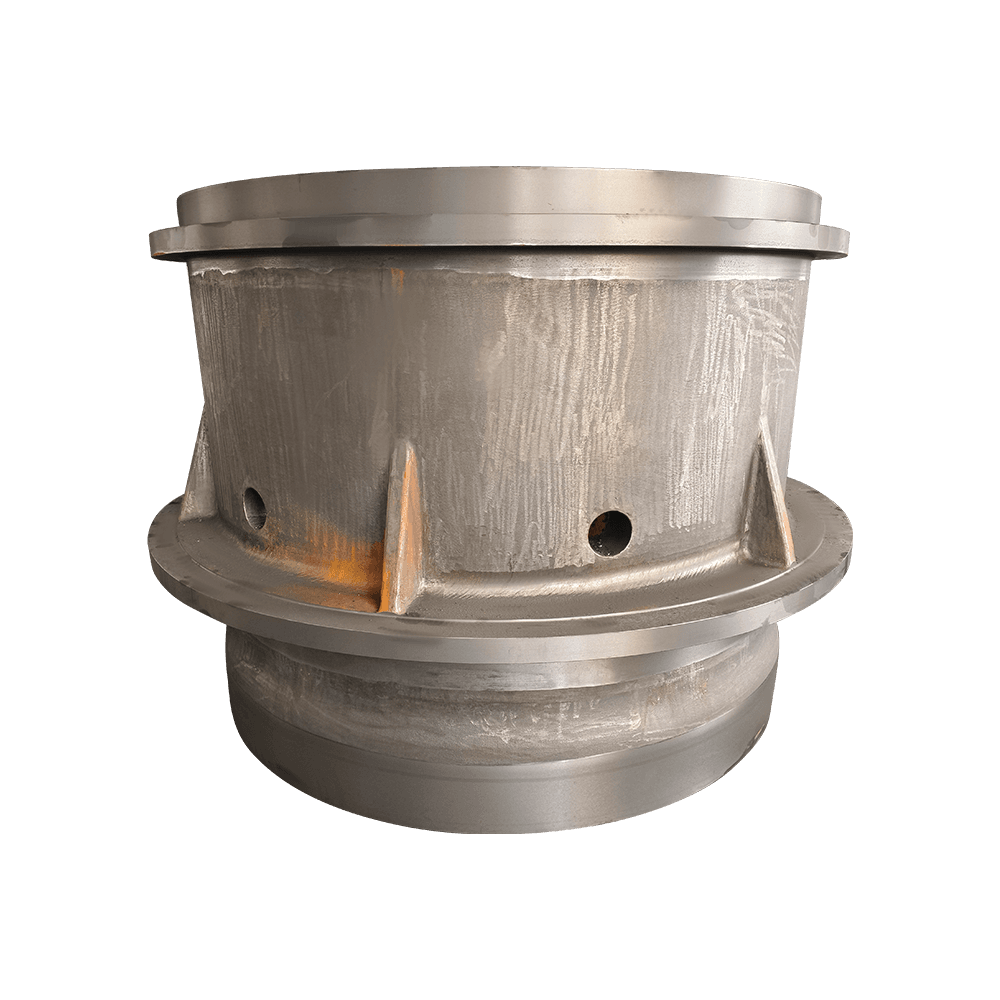

Material Selection: Rotors are typically made from high-strength alloys such as stainless steel, titanium, or nickel-based superalloys. These materials offer excellent resistance to wear, corrosion, and high temperatures, ensuring longevity and reliability in harsh operating conditions.

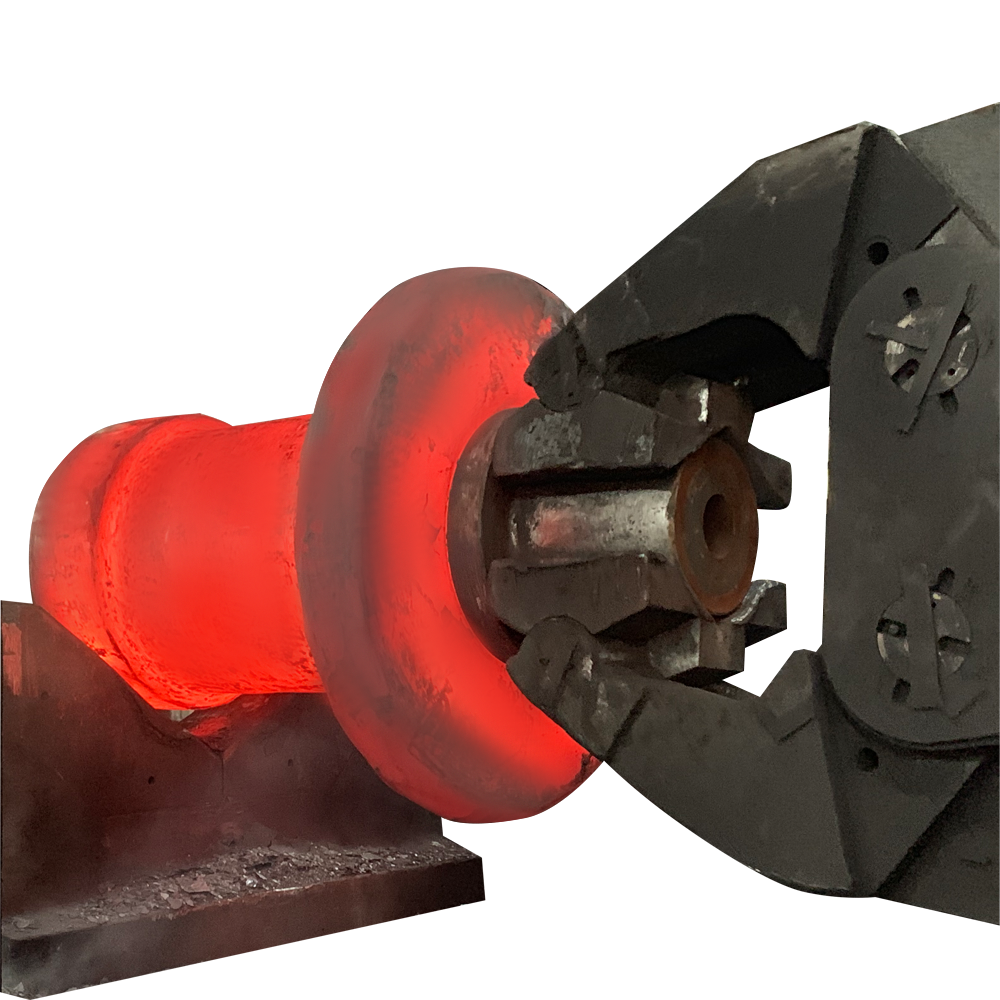

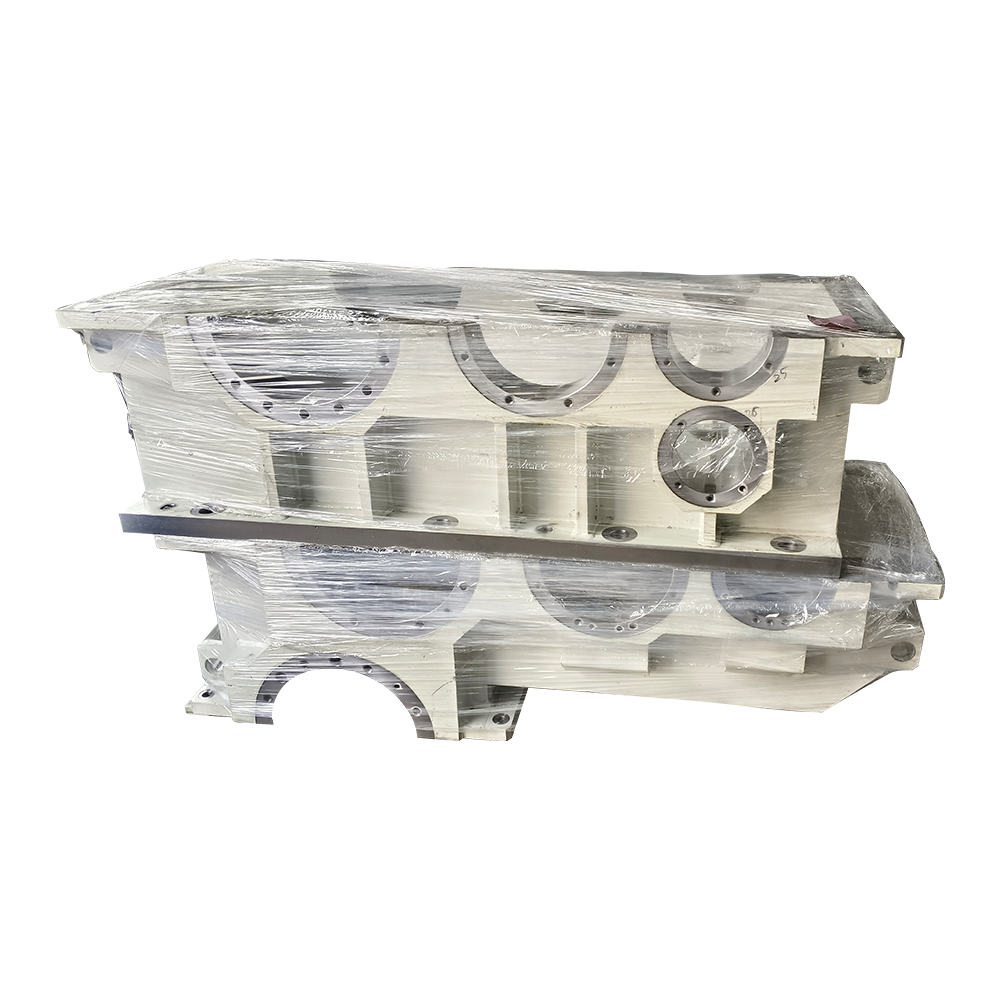

Precision Engineering: The manufacturing process for compressor rotors involves precision machining and balancing to ensure minimal vibration and noise during operation. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are employed to achieve the high tolerances required.

Aerodynamic Efficiency: The rotor blades are designed to optimize aerodynamic performance, reducing energy consumption and enhancing compression efficiency. Computational fluid dynamics (CFD) simulations are often used to refine blade shapes and configurations.

Operational Challenges and Maintenance

Large compressor shaft rotors operate under extreme conditions, including high rotational speeds, pressures, and temperatures. As such, they are subject to significant mechanical stress and potential wear. Regular maintenance and monitoring are critical to ensuring their longevity and performance. Common maintenance practices include:

Vibration Analysis: Monitoring rotor vibrations can detect imbalances or misalignments early, preventing catastrophic failures.

Lubrication Management: Proper lubrication reduces friction and wear, extending the life of the rotor and associated components.

Regular Inspections: Routine inspections and non-destructive testing (NDT) techniques help identify cracks, corrosion, or other defects that could compromise rotor integrity.

English

English 中文简体

中文简体 русский

русский 日本語

日本語 Español

Español